Rapid Alloy Development Techniques for PBF-LB: Systematic study of microstructure formation during AM for Ni-base superalloys

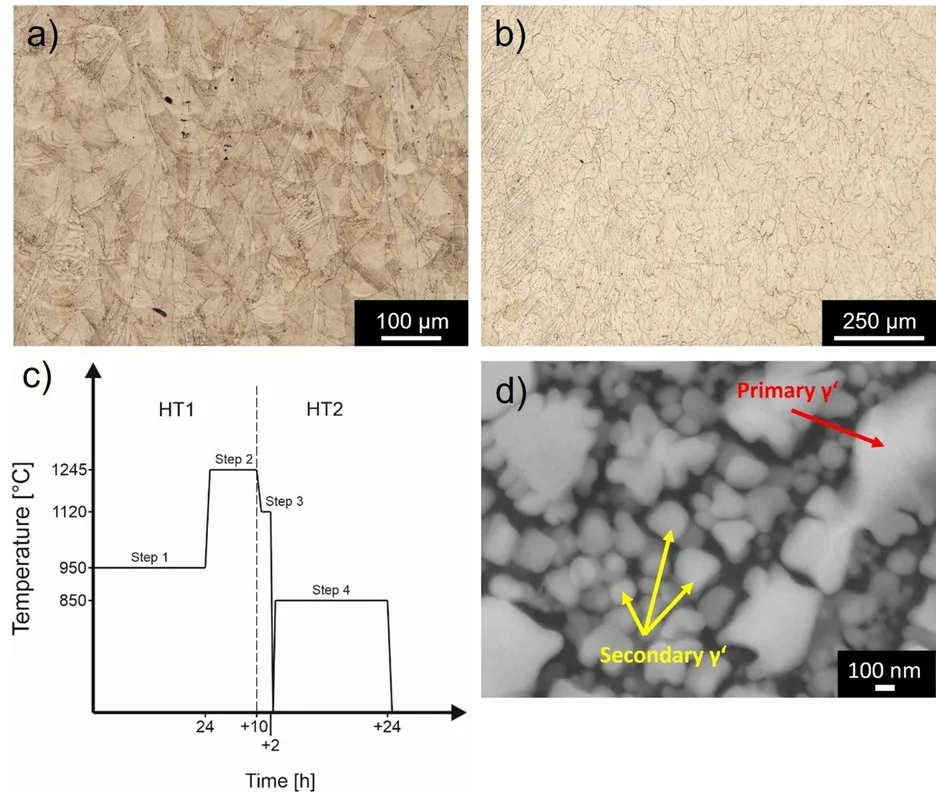

Additive manufacturing (AM) of Ni-based superalloys has emerged as a promising method for fabricating complex components with tailored properties. However, a significant challenge associated with the manufacturing process is the formation of excessively small grains (Figure a), which can lead to suboptimal mechanical properties. In the as-manufactured condition, additively manufactured Ni-based superalloys often exhibit a fine-grained and equiaxed grain structures due to the rapid solidification rates and high cooling rates inherent in the AM process. The small grain size is influenced by parameters such as laser power, scanning speed, powder characteristics, and heat treatment conditions. Insufficient thermal energy and limited diffusion time during solidification contribute to the formation of small grains. Additionally, the distribution of γ' – Ni3Al precipitates, which significantly contribute to the alloy's strength and thermal stability, can be affected during additive manufacturing. The γ' precipitates form in the alloy's matrix and provide strengthening through particle-hardening mechanisms. However, the localized heating and cooling during additive manufacturing can alter the size, morphology, and distribution of the γ' precipitates, leading to an uneven distribution or even dissolution of these strengthening phases. The presence of excessively small grains in additively manufactured Ni-based superalloys can have detrimental effects on mechanical properties, especially high temperature properties such as creep resistance. To mitigate the negative impact of small grain size, various approaches have been explored. Optimization of processing parameters, such as adjusting laser power and scanning speed, can help promote larger grain growth during solidification. Post-processing treatments, including heat treatments (Figure c), can be employed to induce controlled grain growth and refine the microstructure (Figure b), thereby enhancing mechanical properties.

In conclusion, the presence of excessively small grains in additively manufactured Ni-based superalloys presents a significant challenge to achieving desirable mechanical properties. Understanding the factors influencing grain size and developing strategies to control and optimize grain growth are critical for improving the performance and reliability of these alloys. Continued research and development efforts are necessary to overcome this limitation and fully unlock the potential of additively manufactured Ni-based superalloys in demanding applications.