In-situ Absorbance Measurement for High Throughput Process Window Identification in PBF-LB/M

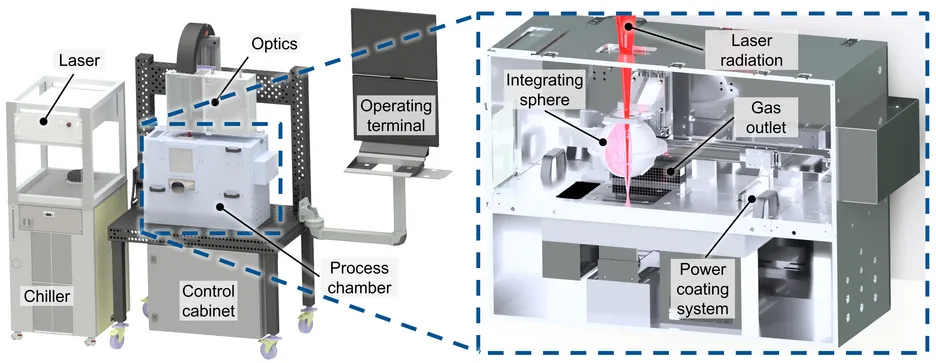

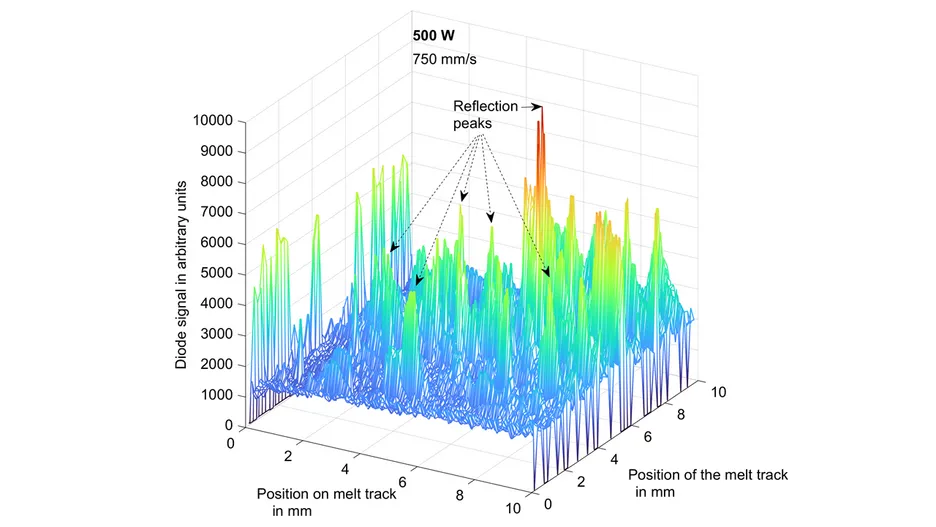

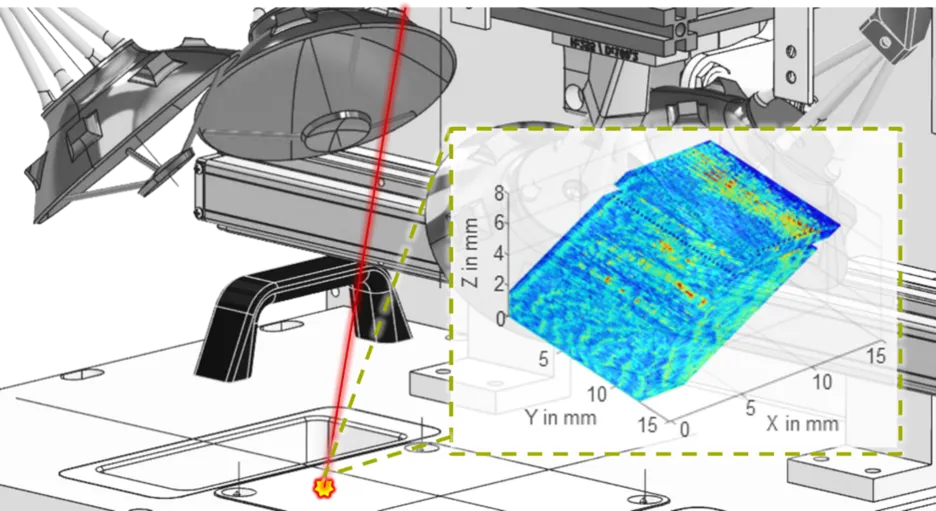

The variety of available materials in powder bed fusion of metals using a laser beam (PBF-LB/M) is currently still very limited. One reason for this is the costly and time-consuming qualification of novel materials. This goes hand in hand with the multi-stage and sequential qualification process for novel materials. In PBF-LB/M extensive parameter studies under varying process settings are followed by a time-consuming evaluation of the manufactured test coupons, in order to determine the suitable parameter settings for high-quality production. This experimental approach for qualifying novel materials is essential, since the highly dynamic and complex interaction between the laser and the material does not allow analytical modeling of the production process. In addition to the PBF-LB/M experiments, the time and cost drivers for qualification of novel materials are the downstream testing of the test coupons. These necessary component tests can be reduced through the targeted collection and evaluation of in-situ process information. The InsighT project explores solutions to identify material and process parameter dependent process regimes by in-situ measurement of the absorption behavior. In addition, the stability of the absorption signal should be associated with a stable laser-material interaction and thus with a stable process. Signal analysis is easy to automate, allowing real-time material qualification. The investigated high-throughput approach promises a fast and cost-effective way to qualify materials for PBF-LB/M. This helps introduce new materials into the industry and allows parts to be manufactured from materials tailored to the application. This industrial applicability is examined through the exemplary integration into a state-of-the-art industrial manufacturing system.

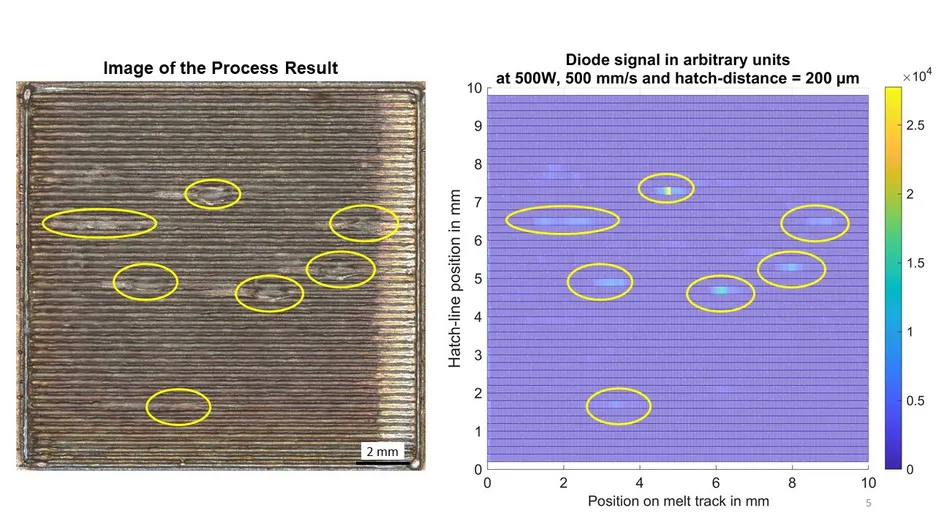

Surface Correlation: Example of visible correlation (marked in yellow) between integrating sphere signal peaks and surface irregularities for 500 W and 500 mm/s

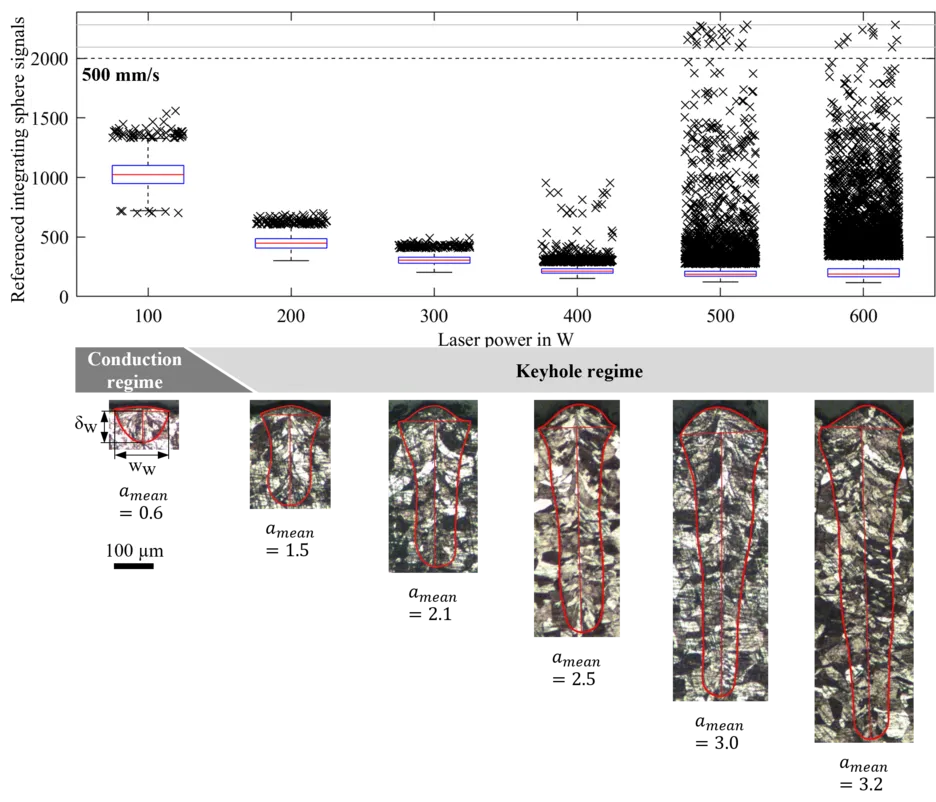

Threshold Detection: Combined visualization of the reference integrating sphere boxplot at the top, the assignment of the parameter specific prevailing process regime in the middle, and corresponding exemplary micrograph images at the bottom for 100 W to 600W at 500 mm/s