Multi-scale modeling of PBF-LB/M using particle methods

Background

Powder Bed Fusion of Metals using a Laser Beam (PBF-LB/M) is increasingly utilized for the fabrication of complex parts in various industrial sectors. Enabling a robust and reproducible manufacturing process is one of the main goals in view of the future success of PBF-LB/M. To enhance the understanding of the complex interplay of the relevant physical phenomena, both experiments and simulations can deliver valuable insight into the process. On the one hand, experimental investigations can be considered as ‘ground-truth’, as they agree most closely with the actual industrial process. On the other hand, data assimilation (i.e. measurements) of high quality is very limited as it is impossible to measure, e.g., transient temperature profiles or geometrical information of the highly dynamic melt pool during the experiment. Contrarily, numerical simulations allow to monitor non-invasively any quantity of interest with “arbitrary” temporal and spatial resolution (within the limits of the numerical settings). However, the challenge of so-called virtual twins is to ensure equivalence in the physical effects with the real problem.

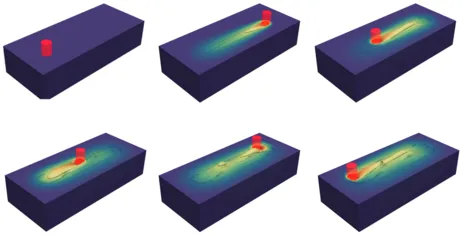

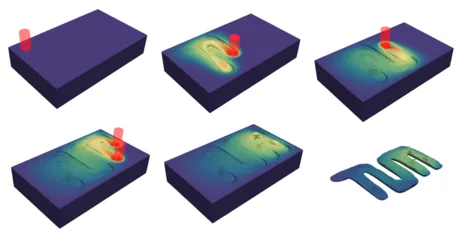

We have developed a SPH-based simulation framework to simulate the melt pool dynamics of powder-bed fusion with a laser beam for metals, see Figure 1. The current modeling is focusing on Fluid Mechanics and Thermodynamics, as the complex physical phenomena inside the hot melt pool are strongly affecting the process and resulting part properties. The laser energy input is considering reflections via Ray-tracing and is capable of predicting the conduction-mode to keyhole-mode transition. Furthermore, surface-tension effects including Marangoni forces, phase-change with heat transfer together with a Recoil – pressure model for evaporation are considered.

Project objective

We aim to develop a multi-scale approach to couple the melt pool dynamics with the solidification process to characterize the resulting material. During solidification, the local species concentrations and temporal temperature profiles manipulate the structural conditions and need to be taken into account. The shape, distribution and composition of the grains determine the material properties like strength, ductility and susceptibility to cracking. The challenge in coupling the two mechanisms is their scale separation in space and time. The typical microscale for solidification is O(µm,ns), whereas the melt pool mesoscale is O(mm,ms).