Simulation and optimization of a High Velocity Oxygen Fuel (HVOF) coating process

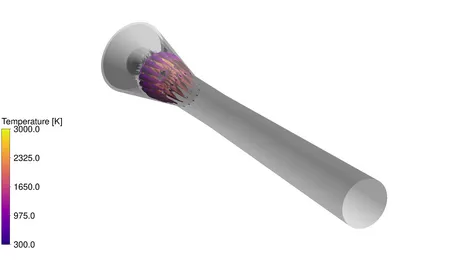

A typical HVOF thermal spraying device combusts oxygen and a gaseous or liquid fuel to provide a desired total pressure and temperature level in its combustion chamber. Then, a coating powder in an inert carrier gas stream is injected into the uniformly heated hot gas stream generated by the combustion. Depending on the flow temperature and selected coating material, the powder transforms into a molten or semi-molten state. The high-energy gas-powder mixture accelerates through a converging-diverging water-cooled Laval nozzle and reaches supersonic speed. The supersonic jet discharges into a gaseous atmosphere and deposits the particles onto a target surface. The particles’ high impact temperature and kinetic energy lead to the formation of a dense coating with desirable characteristics for various industries such as aerospace, automotive, power generation, and medical sciences. The following schematic presents a typical HVOF spraying device developed by Oerlikon Metco.

Customers’ demands towards wider operating conditions and powder materials necessitate developments and improvements of current HVOF devices to enable stable device operation with minimum down times due to in-nozzle erosion and unwanted in-nozzle particle deposition. Such design optimizations require in-depth knowledge of all involved physical processes, such as the combustion, the mixing of combusted gas with particles and carrier gas, and the expected characteristics of the supersonic exhaust jet and its interaction with the powder particles.

The project's scope is to develop CFD (computational fluid dynamics) models that allow for predictive numerical simulations of HVOF processes and to assess the effects of operating condition variation on the particle impact characteristics. In our first publication, we investigated the conditions that may lead to particle depositions at the convergent nozzle wall of a typical HVOF device.