Cavitation and Ultra-Sonic Cleaning

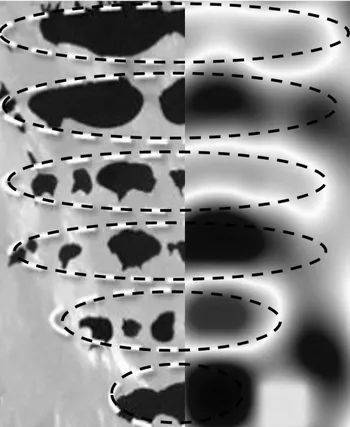

Ultrasonic cleaning systems use vibration generators within a liquid tank to produce standing waves, effectively removing small contaminations from components submerged in the bath. These waves generate pressure fields that excite gas or vapor bubbles near the surfaces of the components, enhancing the cleaning process. Our research focuses on a comprehensive understanding and optimization of the cleaning mechanism by exploring various parameters such as frequency, intensity, and tank design. To achieve this, we utilize the advanced and differentiable compressible flow solver JAX-Fluids (https://github.com/tumaer/JAXFLUIDS). This framework allows us to bridge the gap in scale separation between cavitation dynamics and process scales, leading to more precise numerical simulations and improved cleaning predictions. Key objectives include the investigation of advanced numerical methods for modeling ultrasonic cleaning processes. Furthermore, we implement and validate new computational models against theoretical solutions and experimental data. Finally, the goal is to develop physics-informed and data-driven machine learning models to efficiently predict key physical processes in ultrasonic cleaning.